Project Description

Automotive sector.

APRIM is approved by the most demanding companies in the automotive industry. We have ISO / TS 16949 since 2004.

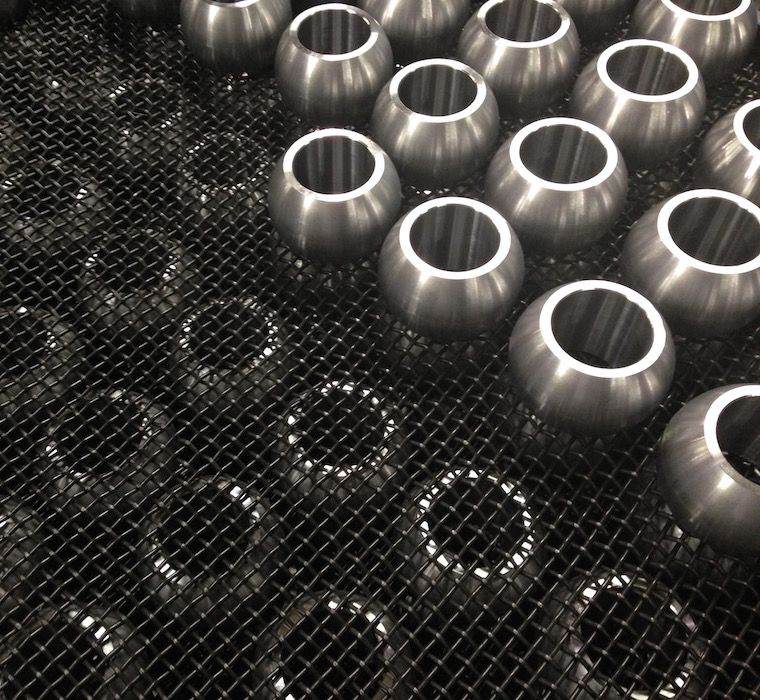

Complex Parts

We have proven over time to be the best suppliers for our customers in what refers to the most complex parts.

Flexibility in diameters

Large diameters components for different industries, such as agriculture. Diameters up to 120mm.

Also in Decolletage

Among the more than 1000 different references that we manufacture each year there are different types of parts and materials.

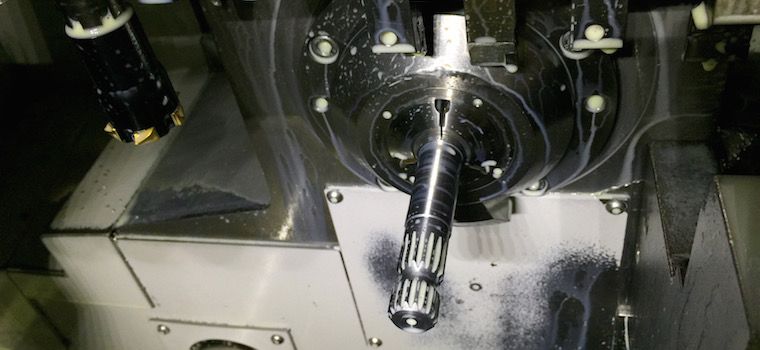

Mobile heads Decolletage

Swiss Machining Swiss Turning or tailstock is a variety of turning in which the bar is fed through a guide bushing that allows always machined in the same level of the point of support, eliminating vibration problems cantilevered.

This makes mobile heads decolletage especially useful for machining slender components; long and thin.

APRIM has several machines of this type. By having complete with comb machines, turret and workstation for second operations, ensuring to solve the most complex parts.

We want to give the best…

… expirence

Sobre APRIM

We specialize in manufacturing serial middle and high volume as well as heat treatments and finishes, including CNC turning, decolletage, milling, drilling, tapping, broaching, grinding, heat treatment, induction hardening of parts up to 2 m, ball mill, coating, etc.

Nuestra historia y el Decoletaje

APRIM is established in 1965 with a core activity focused on the manufacture and machining of parts and assemblies destined for the Automotive Industry and Transport, APRIM then begins production. Over time, APRIM has evolved to offer a wide diversification of services including manufacturing and assembly kits sets with not only mechanical components, also pneumatic, electric, electronic, etc.